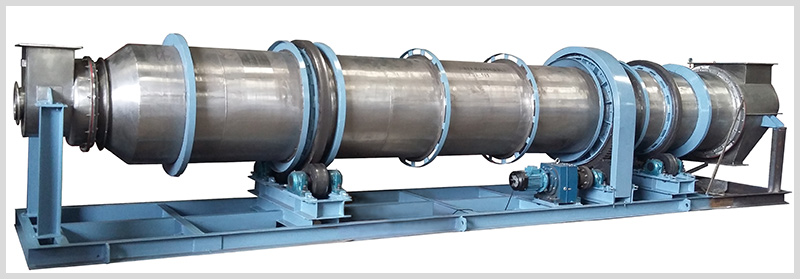

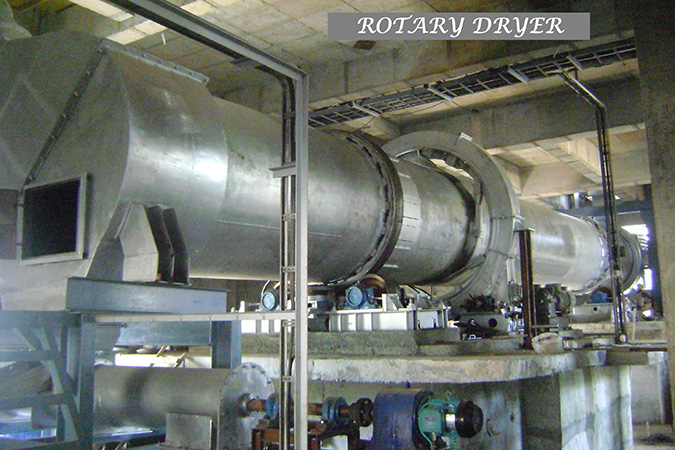

Rotary Dryers/Coolers are widely used in the Industry for drying/cooling of reasonably free flowing materials.AVM offers Customized Rotary Drying Systems with a variety of Configurations. DIRECT ROTARY DRYERS COOLER The material to be dried/cooled comes in direct contact with the drying/cooling media. The dryer comprises of a rotating shell supported on rollers/tyres and driven by means of suitable drive arrangement. Drying/Cooling media(Air/Gas)is admitted through stationary hood at one end taken out from stationary hood from other end. Feed is admitted through suitable feeding mechanism like Screw feeder/Chute. The rotating shell is provided with a specially designed material showering mechanism like Lifters/Garland Chains etc. Shell inclination rotating speed facilitate forward movement of the material towards discharge end providing required residence time. Drying (or Cooling) takes place by heat transfer to (or from) showering material with the drying (or Cooling) media within the shell. Product is discharged from the stationary hood through suitable equipment like Flap Valve/Rotary Valve/Screw Conveyor/Chute.